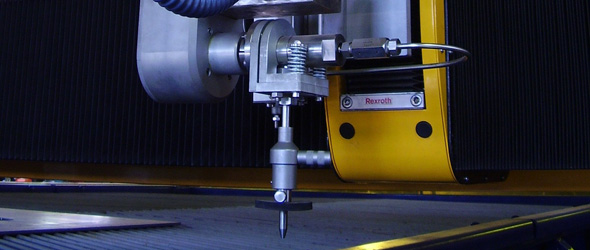

Water Jet Sawing

Water jet laser system is particularly suited for cutting larger diamonds having a size of 5 mm or more. Since no focal adjustment is required, a working distance and cutting depth of up to 30 millimetres is possible. Thus, a diamond can be cut in a single setting rather than from both sides as is the case in conventional lasers.

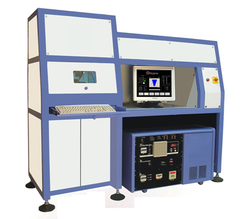

Quazer Laser Sawing

This technology we use for specific high quality rough diamonds with below characteristics:

- Very less probability of breakage in cutting.

- Negligible loss of weight.

- ‘C’ type sawing can be done.

- Pie sawing can be done.

- Rough diamond with heavy tension areas can be cut smoothly.

- Extremely smooth cutting surface can be achieved.

Green Laser Sawing

Smooth cutting surface is obtained. There are least chances of breakage in diamond even with high tension in rough diamond. Double-side Sawing (DSS) is done with lowest weight loss.

Diode Laser Sawing

With the help of Diode laser, Double-side Sawing (DSS) can be done of rough diamond with least weight loss. Breakage ratio is bare minimum even in rough diamond with normal tension. Best surface area in cutting can be obtained.

Shape Cutting

Its a High Temperature boil Process For Flat Cut Diamonds To Increase Its Light & Luster And Also To Remove Some Impurities.